Revolutionizing Tissue Engineering

L'Oréal's Collaborative Breakthrough in 3D Bioprinted Skin Models with University of Oregon

A significant step forward in the field of tissue engineering.

L'Oréal’s scientists from Advanced Research have partnered with the University of Oregon to pioneer the first successful development of an artificial skin model closely resembling natural human skin.

The collaboration has yielded a sophisticated bioprinting method that enables the rapid and precise construction of skin-like structures.

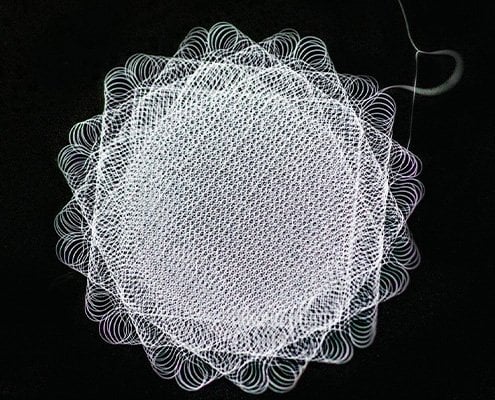

Utilizing a technique known as melt electrowriting (MEW), our researchers, alongside Professor Dalton’s team in University of Oregon, have engineered plastic scaffolds that replicate the extracellular matrix of natural skin.

This is achieved through a network of finely structured 3D printed threads, within which cultured cells are grown to form a bilayered artificial skin.

Uniqueness of this new breakthrough

This bilayer membrane model is the only one capable of producing a fully differentiated skin model with a neosynthesized extracellular matrix (ECM) in only 18 days.

The versatility and adaptability of this model give it many uses including studying how the biological and physical microenvironment impacts the skin, creating pathological skin models, and testing dermo-cosmetics and pharmaceutical treatments on different ages of skin.

Furthermore, it could be an excellent new tool for studying wound healing and development into its use as a graft or wound dressing.

What transformative changes it will bring?

This breakthrough will catalyze transformative changes across the domains of tissue engineering and scientific research by offering:

- Customizable Models: The ability to easily modify the model's overall size and shape, tailor the dermal microenvironment, and organize the extracellular matrix (ECM) means that researchers can create highly specific and controlled conditions. This level of customization facilitates more precise studies of skin biology and pathology, allowing for a better understanding of how various factors affect skin health and disease.

- Accelerated Development: The significant reduction in the time required to reconstruct a model with neosynthesized ECM—from the current standard of 21 to 50 days down to just 18 days—enhances the efficiency of research and development processes.

- Clinical Translation Potential: The use of FDA-approved synthetic materials in the construction of the model is a critical step toward clinical application. It means that these models have the potential to be safely transplanted into humans, paving the way for new therapeutic options, such as personalized skin grafts for burn victims or patients with skin diseases. This could lead to significant improvements in patient care and outcomes.

‘Our collaborative research has not only accelerated the skin reconstruction process but also opened avenues for future applications in skin tissue engineering. We are excited to explore further applications, reinforcing our commitment to innovation and beauty with no animal testing.’

Anne Colonna, Head of Advanced Research, L’Oréal R&I